Insights

KR Decarbonization Magazine

VOL.11 | NOVEMBER 2025

Data-Driven Ship Operational Performance Analysis and Energy-Saving Device Performance Estimation

(ESD: WAPS)

KIM Minsu, Senior Surveyor of KR Ship & Offshore Technology Team

|

Impact of Global Environmental Regulations

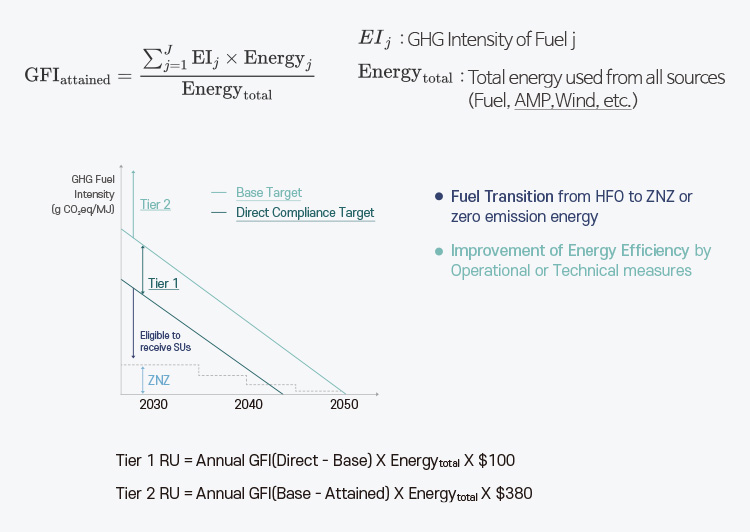

In April this year, the International Maritime Organization (IMO) approved the Net-zero Framework, further accelerating the shipping industry’s transition toward decarbonization. While earlier short-term measures (such as EEDI and CII) were entirely regulation-focused, the new framework expands its scope to promote fuel transition and introduces direct carbon costs on greenhouse gas emissions.

When a vessel uses HFO while calling at European ports, it becomes subject to both IMO and EU regulations. In such cases, assuming the vessel’s CAPEX is set at 1, OPEX is estimated at 2, while carbon costs are expected to reach 4–6. As a result, shipping companies are making every effort to minimize these unexpected carbon costs.

Carbon costs are classified into Tier 1 or Tier 2 depending on whether IMO’s Direct and Base criteria are met. Failure to meet the Base criterion results in Tier 2 classification, which carries punitive costs. Conversely, if the Direct criterion is exceeded by using zero-emission fuels, the shipowner (or shipping company) can receive incentives.

To minimize carbon costs, shipping companies must focus on reducing their annual Greenhouse Gas Fuel Intensity (GFI) while simultaneously improving overall energy efficiency.

▶ GFI can be lowered by switching to alternative fuels to reduce GHG emissions or by utilizing zero-emission energy sources such as shore power, wind, and solar.

▶ Energy efficiency can be improved by managing hull and propeller fouling, maintaining engine efficiency, installing Energy Saving Devices (ESDs), and optimizing operations.

Since fuel transition has been continuously featured in Decarbonization Magazine, this article will instead introduce two key topics: measures to improve energy efficiency and the adoption of wind-assisted propulsion systems (WAPS) as a zero-emission energy source.

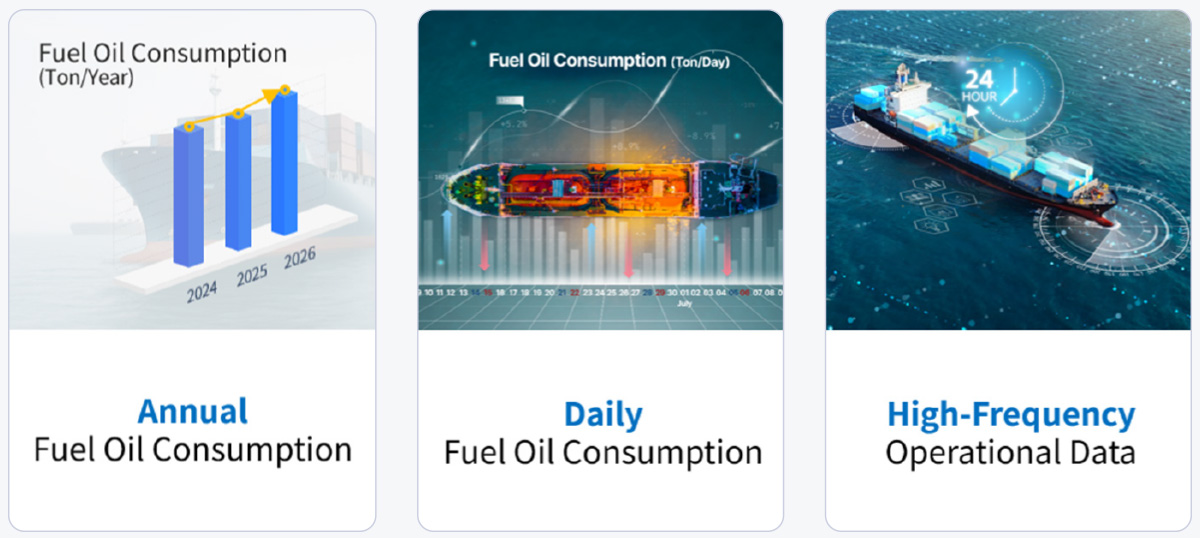

Data-Driven Operational Analysis for Energy Efficiency Improvement

Improving energy efficiency requires an accurate understanding of a vessel’s actual performance, which in turn depends on how effectively shipping companies utilize available data. Typically, shipping companies manage three categories of operational data: annual fuel consumption, daily fuel consumption, and high-frequency measurement data. All shipping companies collect annual fuel consumption data for IMO DCS and EU MRV reporting, while daily fuel consumption data comes from Noon Reports compiled by navigators. High-frequency measurement data are available only on vessels equipped with smart-ship solutions, where sensors record precise data at high sampling frequencies. The following section examines what each type of data can reveal — and how these insights can guide decision-making to improve operational efficiency and support decarbonization strategies.

·Annual Fuel Oil Consumption

Annual fuel consumption data includes voyage distances, sailing times, and actual fuel consumption by type. This dataset is directly applied in CII (Carbon Intensity Indicator) rating calculations and is essential for evaluating annual environmental performance. However, it only provides macro-level information. For instance, ships of the same type may still show differences in CII ratings, but the precise causes cannot be fully explained, as annual data do not sufficiently capture detailed variables such as operating conditions, weather, speed profiles, or loading status.

· Daily Fuel Oil Consumption

Daily fuel consumption data are segmented by operational status (e.g., port stay, port entry and departure operations, voyage), allowing for a clearer understanding of energy consumption patterns at each stage of operation compared to annual fuel consumption data. By utilizing this data, it is possible to distinguish between fuel consumption during port stay and during the main voyage, thereby identifying which segments are causing inefficiencies. Furthermore, when synchronized with KR’s ocean environmental data, daily fuel consumption can be segmented and analyzed by various key factors. However, since a single daily value is used as a representative figure, this inherent limitation prevents detailed variability from being captured, resulting in low accuracy.

· High-Frequency Sensor Data

Modern ships equipped with smart-ship solutions collect high-frequency measurement data through various sensors. This data, recorded at short intervals (seconds or minutes), provides time-series information that includes both navigational data and engine data.

By analyzing this data statistically, it is possible to identify operating conditions that affect vessel performance — such as speed, draft, and rudder angle. When synchronized with KR’s ocean environment data, external factors (including wind speed, wave height, and sea temperature) can also be statistically assessed. In addition, performance variations under different wave and wind conditions, as well as rudder angle data, make it possible to assess the navigator’s operational habits.

By filtering the measurement data to include only segments where sea conditions are calm and navigation is stable, the vessel’s pure technical performance can be estimated.

When sufficient long-term data are accumulated, voyage-based analysis enables the determination of technical performance degradation over time — such as hull and propeller fouling or engine efficiency decline — helping ship operators identify the optimal timing for maintenance.

In cases where sister ships exist, performance comparisons between vessels are also possible. By classifying parameters such as ship performance, maintenance condition, and engine efficiency decline as technical performance, and factors such as port waiting, sea conditions, and navigational practices as operational performance, operators can identify the optimal measures to improve energy efficiency for each vessel.

Among the three types of data available to shipping companies, high-quality measurement data collected through smart ship solutions are essential for accurately assessing vessel performance. Furthermore, long-term data accumulation is indispensable for analyzing performance degradation over time.

Regulatory Impacts on WAPS Performance and Case Studies

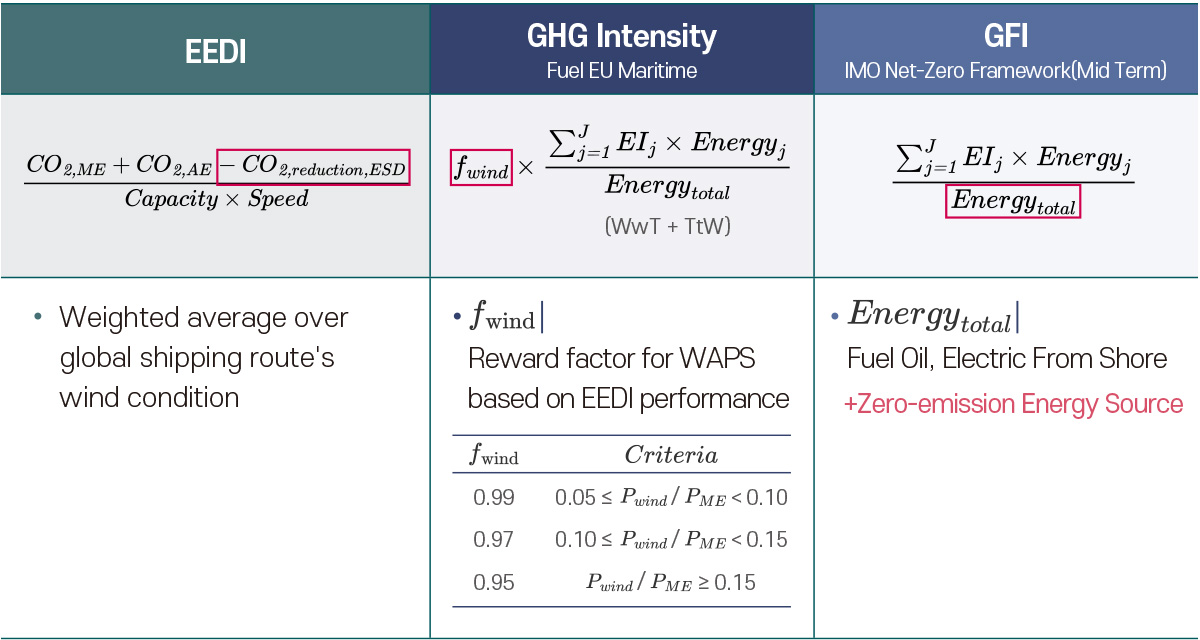

In environmental regulations, incentive schemes are established to reward Energy Saving Devices (ESDs) that contribute to reducing greenhouse gas emissions. Among them, Wind-Assisted Propulsion Systems (WAPS) offer dual benefits compared to other ESDs — simultaneously lowering the GFI and improving energy efficiency, thereby reducing carbon costs.

The dual benefits of WAPS are designed somewhat differently under each regulation. For example, under EEDI, only the top 50% of WAPS performance conditions are reflected, resulting in efficiency values estimated at nearly twice the actual level. In contrast, FuelEU Maritime introduces a reward factor called fwind, which provides an additional 1–5% incentive if WAPS achieves energy savings of 5%, 10%, or 15% or more. Meanwhile, the IMO Net-Zero Framework is designed to provide dual benefits by adding the contribution of WAPS to the vessel’s total energy use when calculating the GFI. Accordingly, KR has developed a procedure for calculating WAPS efficiency in accordance with the relevant regulations, and has conducted comparative analyses to verify consistency and reliability across different evaluation methods.

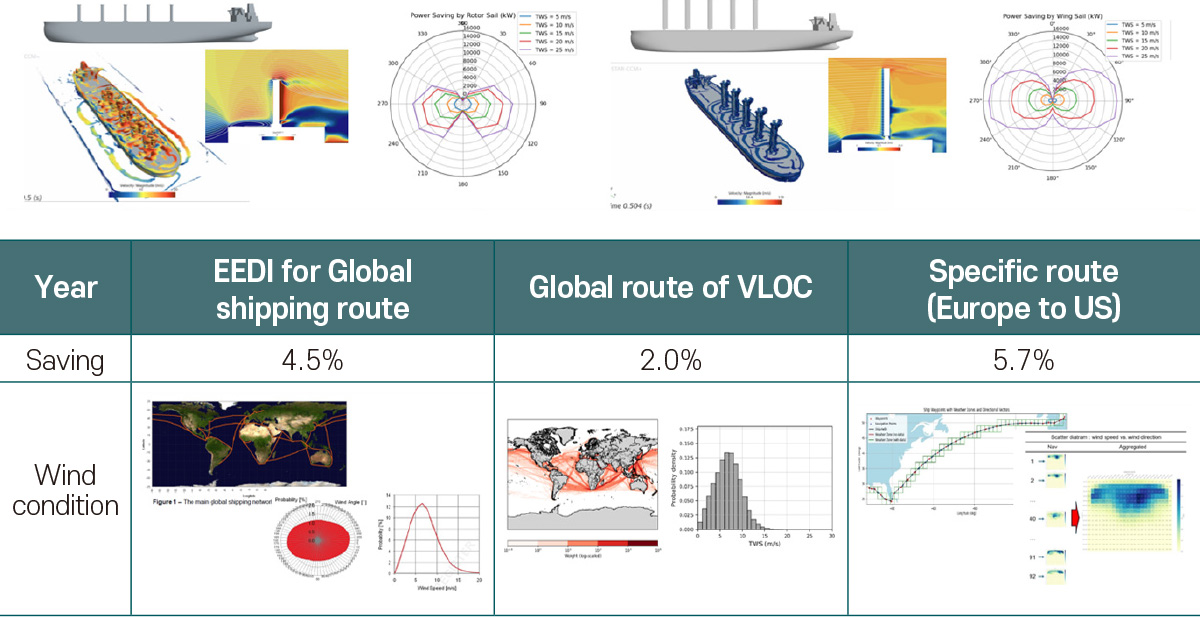

The target vessel was assumed to be a Very Large Ore Carrier (VLOC) equipped with either five rotor sails or five wing sails. As a first step, WAPS performance was evaluated through Computational Fluid Dynamics (CFD) analysis, and the results were presented in the form of a performance polar chart. The rotor sail showed limitations in utilizing maximum wind speeds due to the need to maintain an optimal ratio between rotor rotation speed and wind velocity. However, it generated strong thrust under beam and crosswind conditions thanks to the Magnus effect. In comparison, the wing sail requires approximately four times the surface area to produce the same thrust as a rotor sail, but it is not restricted by wind speed and can also generate propulsion under tailwind conditions by harnessing both lift and drag forces. If space efficiency and gust-response safety associated with its larger surface area can be ensured, the wing sail has the potential to deliver superior long-term performance.

KR calculated WAPS efficiency using three evaluation methods based on the rotor sail performance polar chart. The first method applied the EEDI evaluation approach, which estimates efficiency during the design stage without considering the vessel’s actual route. It uses the global route wind direction and speed distribution (Wind Matrix) provided by MEPC. The analysis identified approximately 4.5% power savings; however, since the vessel’s actual route was not reflected, this figure is difficult to interpret as a practical operational effect.

The second method analyzed efficiency by extracting global routes based on the AIS data of the VLOC and synchronizing them with ocean environmental data to construct a Wind Matrix. This analysis showed a power saving of about 2.0%, which is about half the level estimated by the EEDI evaluation method.

Lastly, to verify the maximum effect of WAPS, a Wind Matrix was developed for the North Atlantic route where wind conditions are strong. In this case, efficiency increased by up to 5.7%, even for a very large vessel.

In summary, the performance of WAPS varies significantly depending on the evaluation method and route conditions, highlighting the necessity of precise analysis that reflects actual routes and environmental factors.

Third-Party Verification Guidelines for ESDs

Although WAPS offers dual benefits under environmental regulations, many shipping companies are still reluctant to invest. The main reason is that the high initial installation cost and uncertainty regarding efficiency make it difficult to objectively assess the ROI (Return on Investment). Accordingly, KR is establishing a rational efficiency calculation procedure from a third-party perspective, reflecting actual routes and environmental conditions as examined in the previous case. This initiative is intended to help shipping companies assess investment feasibility based on more realistic criteria. In addition, KR is expanding its scope of services by developing efficiency estimation procedures not only for WAPS but also for various other energy-saving devices — including Onboard Carbon Capture Systems (OCCS), Waste Heat Recovery Systems (WHRS), and passive Energy Saving Devices (ESDs) of Category A type attached to the hull.

Decision Support for Energy Efficiency Improvement

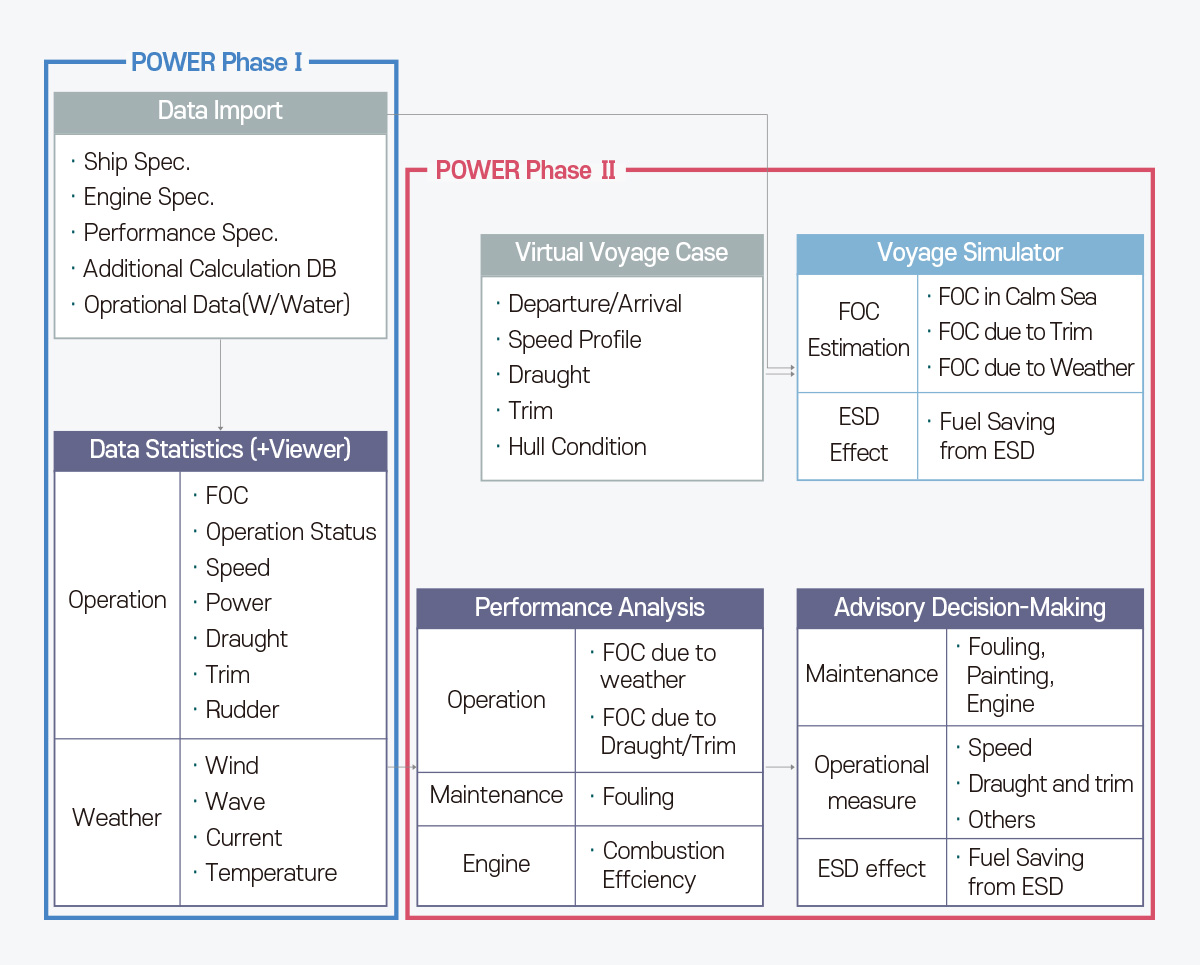

KR is developing an operational data analysis solution called KR-POWER, designed to support data-driven decision-making for energy efficiency improvements. The system analyzes operational performance and estimates the actual effectiveness of various Energy Saving Devices (ESDs). The development is being carried out in two phases. Phase 1, scheduled for release at the end of 2025, will integrate shipowners’ operational data with KR’s environmental and AIS data to provide statistical visualization of operational characteristics, weather conditions, and fuel consumption.

Phase 2, scheduled for release by the end of 2026, will further expand its functions to data visualization and performance analysis based on measurement data. Through this enhancement, the system will enable the quantification of fuel consumption by contributing factors, as well as the identification of performance degradation resulting from hull fouling and declining engine combustion efficiency. Building on these analysis results, the system will provide capabilities to predict fuel consumption under hypothetical operating conditions such as draft, trim, and speed, and to simulate the effects of ESDs.

This enables shipping companies to pre-evaluate energy efficiency improvement strategies under various operating conditions. They can assess hull and propeller fouling, coating condition, and engine efficiency from a maintenance perspective; evaluate performance in relation to speed, draft, and trim from an operational perspective; and review the effectiveness of ESDs from a technical perspective, thereby supporting more rational decision-making. In addition, KR is working to integrate shipyard smart ship solutions and shipping companies’ Fleet Control Center data with the KR Smart Ship Platform as part of this implementation.

- A New Pillar in Shipping Decarbonization: Biofuels

- Status of Biofuel Use in Shipping: Still at an Early Stage, but Growing Rapidly

- Production Processes and Characteristics of FAME and HVO

- Technical Considerations: Guidelines for the Safe and Efficient Use of Biofuels

- Key Technical and Operational Risks of Biofuels and Mitigation Measures

- Safe Transition to Biofuels: KR Notation “SusBio”

Biofuel Series – Part Ⅰ

Biofuels in the Pathway to Net-Zero:

Technical Challenges and Operational Perspectives

HA Seungman, Principal Surveyor of KR Machinery Rule Development Team

|

This is the first installment in KR’s Biofuel Series. Coming up in the next issue, Part 2 — co-authored with VISWA Group — will take a closer look at the operational challenges, quality issues, and case studies of biodiesel blends in marine fuels

A New Pillar in Shipping Decarbonization: Biofuels

Biofuels are fuels derived from biomass—such as vegetable oils, agricultural residues, and waste-based materials—through processing and refining. In the maritime sector, they are attracting increasing attention as alternative fuels that share physical and chemical properties with conventional fossil fuels while contributing to the achievement of Net-Zero targets.

Currently, the main types of biofuels under consideration include Fatty Acid Methyl Ester (FAME), Hydrotreated Vegetable Oil (HVO), bio-methanol, bio-LNG (Liquefied Bio-Gas), ethanol, Straight Vegetable Oil (SVO), Fischer–Tropsch diesel (F-T diesel), upgraded pyrolysis oil, and Dimethyl Ether (DME). Among these, FAME and HVO stand out as the most promising options for international shipping, as they can be used as drop-in fuels without requiring major modifications to existing ship fuel systems.

In other words, biofuels can either fully replace conventional fuels or be blended in varying proportions, making short-term transitions more feasible.

· FAME: Already relatively widespread, with an increasing number of cases where it is blended with conventional fuels, but requires careful management due to its lower oxidation stability and poor long-term storability.

· HVO: Chemically similar to diesel, offering excellent compatibility with existing engines and higher oxidation stability suitable for long-term storage. However, cost factors remain a constraint.

Biofuels thus present a wide spectrum of types and characteristics, and their respective strengths and weaknesses will directly influence future fuel choices and regulatory strategies in the maritime sector.

Status of Biofuel Use in Shipping: Still at an Early Stage, but Growing Rapidly

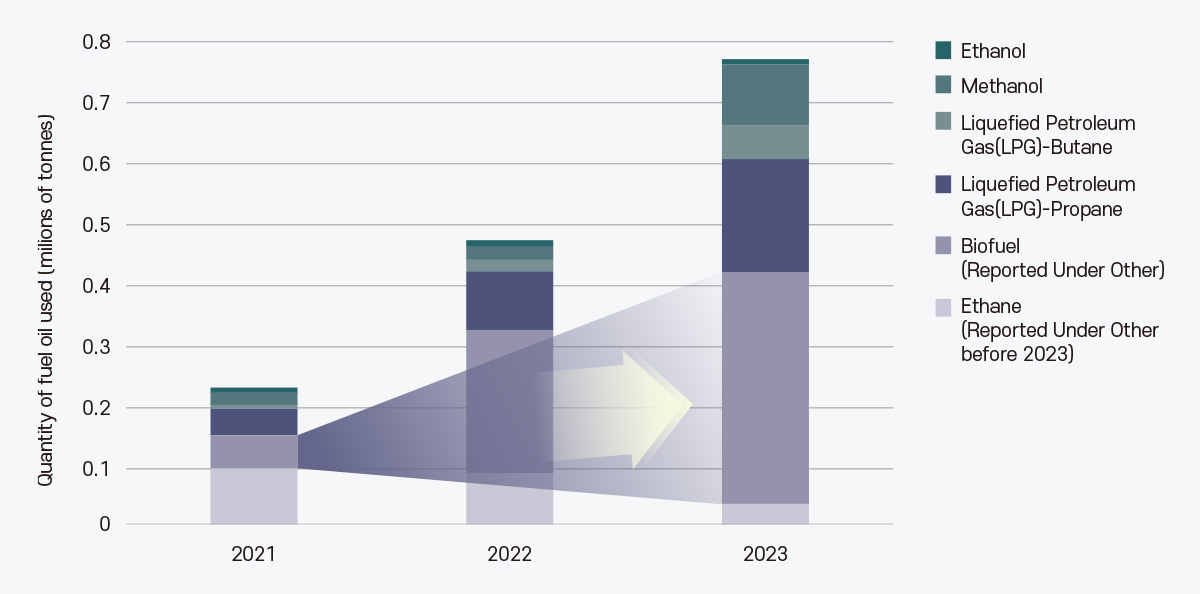

As of 2023, the vast majority of global biofuel consumption — around 99% — remains concentrated in road transport, with aviation accounting for about 0.5% and shipping only 0.6%. In terms of total marine energy use, this translates to a share of just 0.3%.

Although the volume is still marginal, it is noteworthy that since the IMO DCS (Data Collection System) reporting began in earnest in 2021, biofuel use in shipping has shown a steady year-on-year increase, as illustrated in the bar chart below. This indicates that, while biofuels currently represent only a small piece of the overall maritime energy mix, their share is expected to expand rapidly as regulatory discussions intensify and shipping industry interest grows.

Production Processes and Characteristics of FAME and HVO

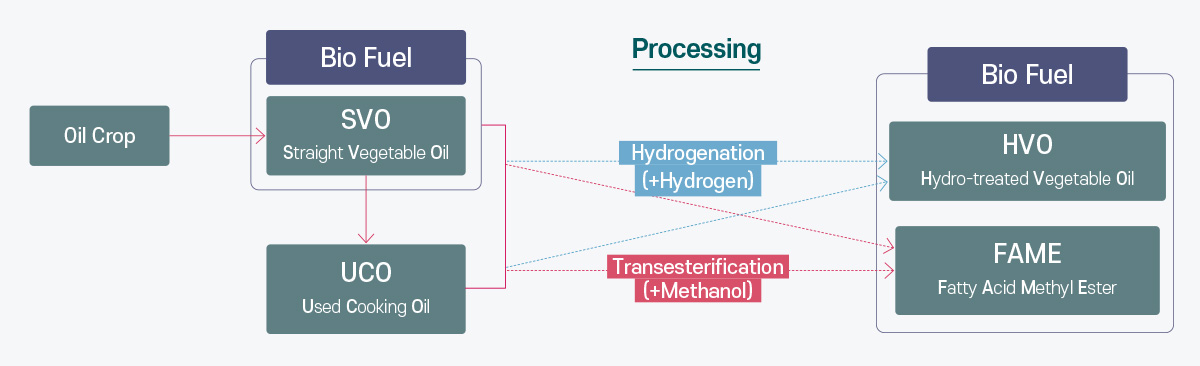

Among the various types of biofuels, those being most rapidly applied in the shipping industry are Fatty Acid Methyl Ester (FAME) and Hydrotreated Vegetable Oil (HVO). Both are derived from oil crops, straight vegetable oil (SVO) or used cooking oil (UCO), but their production processes differ significantly.

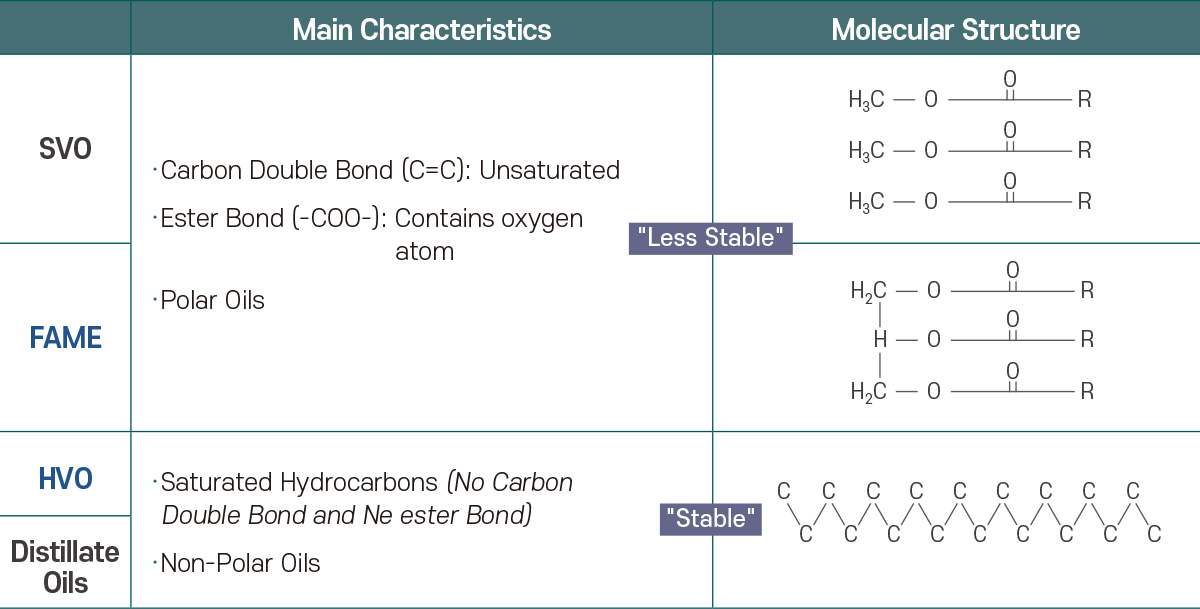

▶FAME is produced through a transesterification process in which methanol is added to the feedstock oil. Because the resulting ester bonds retain oxygen atoms, the fuel exhibits polar characteristics and is highly susceptible to oxidation and degradation. Consequently, it deteriorates easily during long-term storage and is considered less stable.

▶HVO, on the other hand, is produced via hydrogenation, in which hydrogen is added to the feedstock oil to remove unsaturated bonds and oxygen. This process converts the oil into a structure of saturated hydrocarbons, chemically almost identical to petroleum diesel. As a result, HVO is non-polar, highly resistant to oxidation, and well suited for long-term storage.

These structural differences have important implications for actual ship operations:

▶FAME offers advantages in terms of cost and supply availability, but its lower oxidation stability and storability demand strict management.

▶HVO provides excellent stability and compatibility, but its feedstock requirements and higher production costs remain barriers to wider market adoption.

A further challenge in the adoption of biofuels lies in the competition between international shipping and aviation. Aviation has limited alternatives for decarbonization, making the use of Sustainable Aviation Fuel (SAF) indispensable. Within SAF, HVO is widely recognized under the name Hydroprocessed Esters and Fatty Acids (HEFA) and has become the primary feedstock pathway. Because aviation has fewer alternatives and greater willingness to pay premium prices, the large-scale introduction of HVO into shipping faces significant practical constraints.

For this reason, this article will focus primarily on the technical and operational considerations of FAME, which is more likely to see wider application in shipping.

Technical Considerations: Guidelines for the Safe and Efficient Use of Biofuels

To ensure the safe and efficient use of biofuels in ships, it is essential to carefully examine and manage the potential risks arising from their inherent fuel properties. Unlike conventional fossil fuels, the distinct chemical characteristics of biofuels directly affect engine performance and fuel system integrity.

In particular, FAME contains oxygen atoms in its molecular structure, which introduces a range of technical risks. Identifying these risks in advance and implementing appropriate preventive measures is the key to stable ship operations.

Key Technical and Operational Risks of Biofuels and Mitigation Measures

1. Oxidation Stability and Long-Term Storage Issues

FAME is chemically prone to oxidation, which can cause the fuel to degrade and form sludge or acidic compounds. This leads not only to reduced fuel quality but also to corrosion of engine components and filter clogging.

▶Mitigation|Biofuels should ideally be consumed within three months rather than stored long-term. For extended storage, regular fuel quality analysis is recommended, and antioxidants should be added as needed to improve stability. Recently, NYK Group commercialized an antioxidant called Bioxiguard for biodiesel, demonstrating the shipping industry’s efforts to tackle this issue.

2. Material Compatibility

Biofuels may react with rubber, plastic, or certain metallic components in the fuel system, leading to damage such as fuel leakage or part failure.

▶Mitigation|Review material compatibility before use and replace them with biofuel-resistant materials such as fluorocarbon rubber (Viton) or Teflon. Materials like nitrile rubber and neoprene should be avoided, as they may swell or weaken when exposed to biofuels.

3. Risks from Specific Compounds

Depending on the feedstock or production process, biofuels may contain unexpected reactive compounds that can severely damage fuel systems. For example, CNSL (Cashew Nut Shell Liquid) contains highly reactive substances such as cardol and anacardic acid, which accelerate corrosion and wear of metallic parts and form polymers that clog filters. Other problematic compounds have also been reported, such as:

·Estonian Shale Oil: Risk of reduced fuel stability

·Phenolic Compounds: Can destabilize fuel properties

·Biodiesel Residues(e.g., free fatty acids, mono-/di-/triglycerides): Accelerate oxidation and degradation

·Rosin Acids: Highly reactive under oxidative conditions, reducing fuel stability

▶Mitigation|Require full disclosure of feedstock and production process details from suppliers, and rigorously check Certificates of Quality (CoQ) before bunkering. If necessary, conduct detailed testing using GCMS (Gas Chromatography-Mass Spectrometry) to detect harmful compounds in advance.

4. Lube Oil Contamination and Performance Degradation

In four-stroke engines, FAME-based fuels can leak into the lubricating oil during combustion, lowering oil viscosity. This leads to reduced lubrication performance and accelerated engine wear.

▶Mitigation|Regularly monitor FAME concentration in lube oil using FTIR (Fourier Transform Infrared Spectroscopy). Adjust oil change intervals flexibly, not just by fixed time schedules, but based on contamination levels and viscosity changes.

5. Sludge Formation and Filter Clogging

Because of FAME’s instability and hygroscopic nature, sludge can accumulate more frequently in fuel tanks and purifiers. This increases the risk of filter clogging, which may disrupt operations.

▶Mitigation|Drain tanks regularly to prevent water accumulation, adjust sludge discharge frequency in purifiers, and fine-tune gravity disk settings to match the characteristics of biofuels. In the early adoption phase, it is essential to stock sufficient spare filters to prepare for clogging incidents.

6. Engine Performance

FAME has a lower calorific value compared to fossil fuels, which can result in increased fuel consumption or reduced engine output at high loads. Mechanically controlled (MC) engines are more vulnerable to these effects than electronically controlled (ME) engines.

▶Mitigation|Confirm calorific value before use, and optimize engine settings (e.g., ignition timing) if necessary to minimize performance loss. Lubricity improvers can also be used to prevent mechanical wear.

7. Need for Additional Testing and Risk Assessment

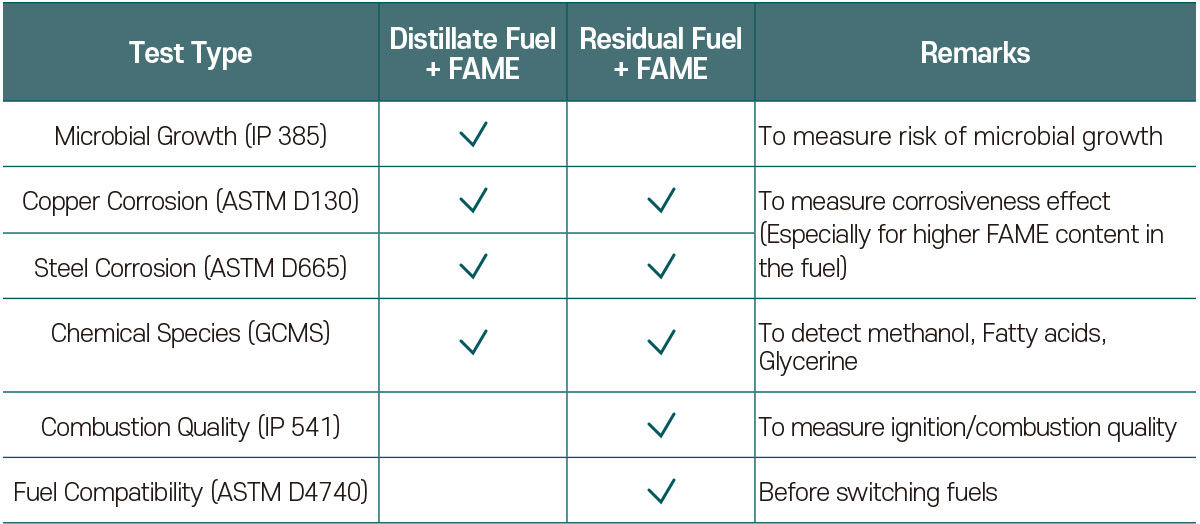

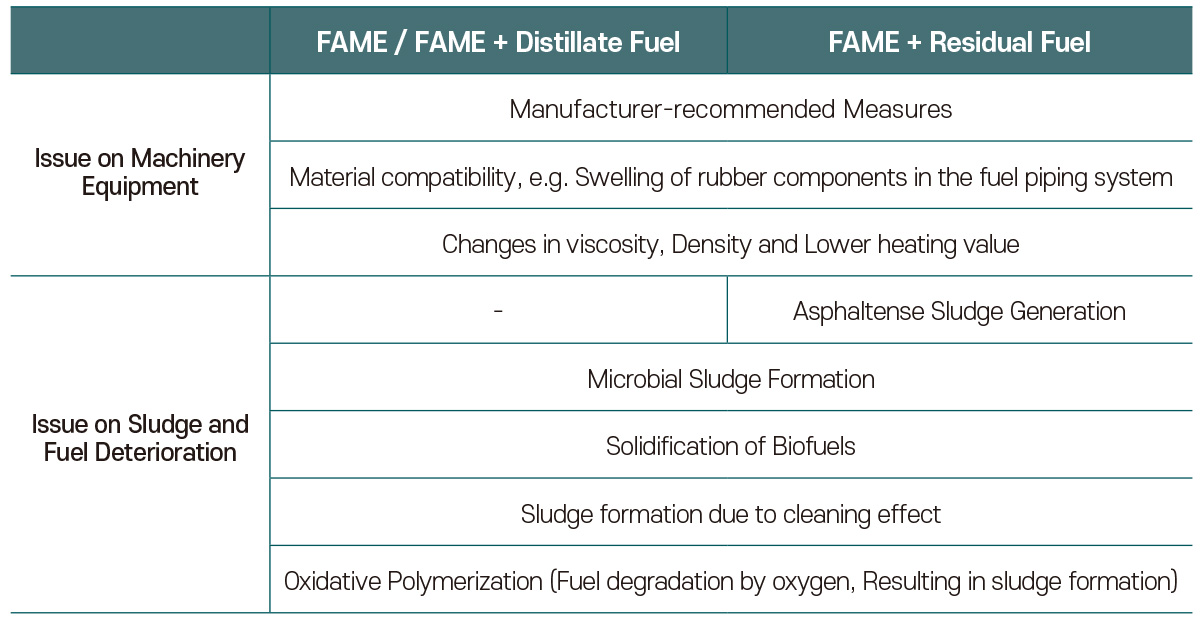

Unlike petroleum-based fuels, FAME contains oxygen, which can cause oxidation, corrosion, and microbial growth. Compliance with international standards (e.g., ISO 8217) alone is not sufficient to guarantee safety; additional testing is strongly recommended.

These technical considerations demonstrate that biofuels are not merely “green fuels,” but require systematic management and preventive maintenance to ensure safe and reliable operation. For this reason, KR recommends conducting risk assessments. The table below summarizes key issues that should be considered during evaluation, and it is essential that shipowners and crew fully understand and prepare for these risks in advance.

| FAME / FAME + Distillate Fuel | FAME + Residual Fuel | |

|---|---|---|

| Issue on Machinery Equipment | Manufacturer-recommended Measures | |

| Material compatibility, e.g. Swelling of rubber components in the fuel piping system | ||

| Changes in viscosity, Density and Lower heating value | ||

| Issue on Sludge and Fuel Deterioration | - | Asphaltense Sludge Generation |

| Microbial Sludge Formation | ||

| Solidification of Biofuels | ||

| Sludge formation due to cleaning effect | ||

| Oxidative Polymerization (Fuel degradation by oxygen, Resulting in sludge formation) | ||

Safe Transition to Biofuels: KR Notation “SusBio”

In international shipping, the use of biofuels is no longer a choice but a necessity. However, the diversity of fuel characteristics and ongoing regulatory uncertainties continue to pose significant challenges for both shipowners and shipyards. Beyond the question of simple usability, the industry urgently requires clear standards that holistically address safety, environmental performance, and operational reliability.

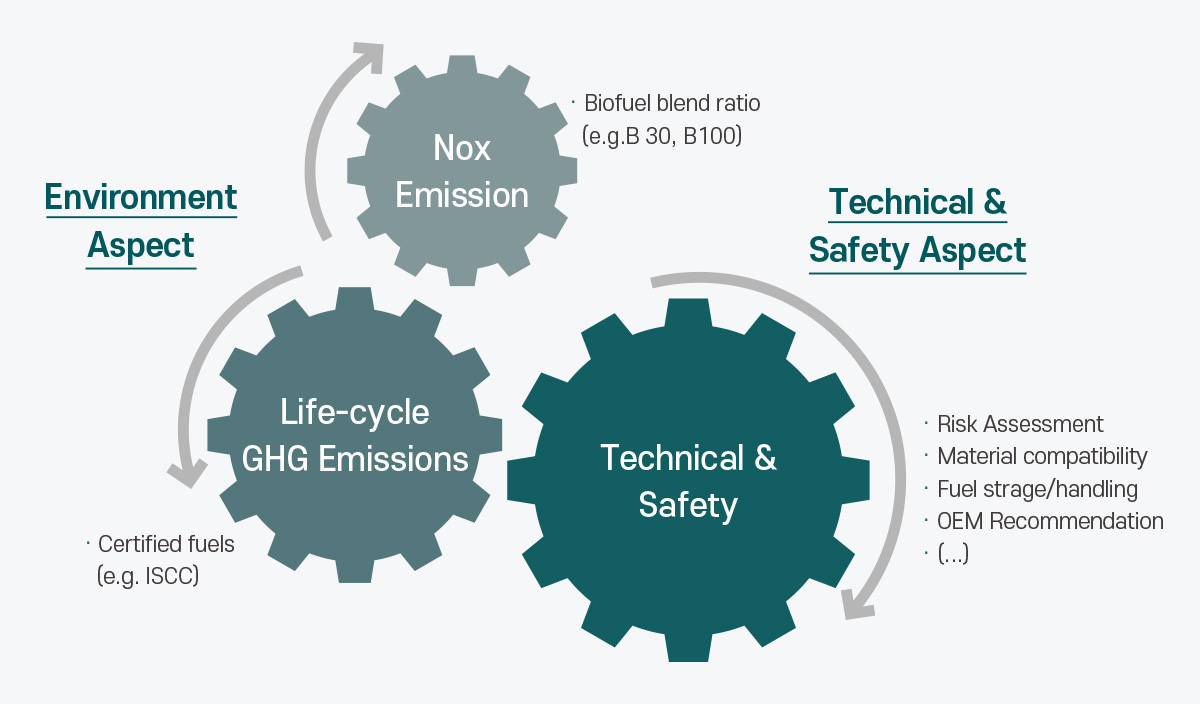

To meet this demand, Korean Register (KR) is developing the “SusBio” (Sustainable Biofuel) notation. SusBio goes far beyond classifying fuels by blend ratios. It provides a comprehensive framework that encompasses life-cycle GHG verification, sustainability certification, NOx compliance, material compatibility, fuel storage and handling requirements, and risk assessment.

KR is also working in close collaboration with shipyards to prepare Standard Design Specifications optimized for biofuel use. By incorporating biofuel readiness at the newbuilding stage, this approach aims to preemptively reduce the additional costs and risks that could arise during future fuel transitions. In parallel, KR is strengthening its technical cooperation with VISWA Group, a leading marine fuel analysis company, to ensure that clients receive the latest insights and data in a timely manner.

Ultimately, the successful adoption of biofuels cannot be achieved by any single player. It requires the alignment of multiple stakeholders: robust safety standards from classification societies, design standardization by shipyards, assured fuel quality from suppliers, and operational expertise from shipowners.