Insights

KR Decarbonization Magazine

VOL.03 | summer 2023

How to Ensure Compliance with CII Criteria for Existing Ships that Depend on HFO

SONG Kanghyun, Head of KR DecarbonizationㆍShip R&D Center |

Comparing and analyzing

|

Choosing the Next Green Fuel

The shipping industry is currently at a critical juncture when it comes to decarbonization, thanks to the International Maritime Organization’s (IMO) decarbonization objectives. These objectives, outlined in the IMO’s GHG Strategy, aim to achieve carbon neutrality by 2050. This means that the industry is facing one of the most important decisions in its history.

Once the IMO 2050 targets are finalized, it is anticipated that the criteria for the Carbon Intensity Index (CII) will undergo significant strengthening after 2027. To comply with these enhanced criteria, the shipping industry will need to employ all available measures and technologies to reduce carbon emissions. It is crucial for the industry to be prepared and proactive in meeting these requirements.

Satisfying the CII criteria is particularly challenging for existing vessels that rely on Heavy Fuel Oil (HFO), which constitutes around 90% of the industry. Retrofitting the engines and fuel supply systems to switch to LNG or methanol as fuels is very expensive , and the additional costs are much higher than for newbuildings. It also entails operational losses during the retrofitting period.

Technological Method 1- Ship Speed Reduction

Various technological and operational methods can be employed to enhance the CII. It is crucial to assess the cost-effectiveness of these technologies. One of the most effective and practical methods is to reduce the speed of a vessel. As vessel resistance is proportional to the cube of velocity, reducing speed significantly reduces fuel consumption. Shipowners need to gradually reduce speed and monitor CII to keep a minimum C-rating or above and comply with the increasingly stringent CII regulations each year. However, there are limitations to reducing speed, and alternative measures to improve CII need to be explored once the minimum acceptable speed from a business perspective is reached.

Technological Method 2– Blending Biofuel as a Drop-in Fuel

Using Energy Saving Devices (ESDs) does not make it easier to increase vessel speed as desired. Therefore, a realistic solution is to blend biofuel as a drop-in fuel, which can address the reduced speed issue. However, biofuel is approximately three times more expensive than HFO, and its production is limited due to feedstock constraints, resulting in price volatility. Furthermore, competition with other industries, such as the aviation and automotive industries, is necessary to secure the fuel supply. Fortunately, the demand in the shipping sector is increasing, leading to expanded infrastructure and increased production from domestic and international energy companies. Shipowners can gradually increase the blend ratio, such as B20, B30, B50 and B100 to comply with the strengthened CII. If penalties or market-based measures like a Carbon Tax are established when receiving CII ratings of D or E in the future, shipowners need to analyze costbenefits during this process to determine the blend ratio.

Technological Method 3- Energy Saving Devices

Considering that biofuel is very expensive, it is essential to explore various ESDs to ensure that not even a drop of fuel is wasted. Although the contribution of each ESD to fuel savings ranges from 2% to 5%, shipowners can save significant costs if fuel prices rise and the payback time decreases. The key to ESD installation also lies in cost-effectiveness. Examples of ESDs include fins, rudder bulbs, ducts, which increase the flow rate entering the propeller to enhance efficiency, replacing the propeller or improving the bulbous bow shape to match the reduced vessel speed, and using low-friction coatings. Additionally, installing fuel-saving devices such as Air Lubrication System’s (ALS), rotor sails, wing sails, and shaft generators could be considered. When installing multiple ESDs simultaneously, the combination can affect efficiency, and careful consideration is needed to select the optimal combination based on vessel type and size. Furthermore, shipowners require third-party verification from institutions with procedures and expertise to objectively validate the performance suggested by the technical providers.

Operational Methods

In terms of operational methods, there are several ways to improve CII in shipping. These include optimizing ship speed, trim optimization, implementing weather routines, optimizing loading and unloading operations at ports, and utilizing shore power.

The effectiveness of operational methods in improving CII can vary depending on the quality of data obtained and the appropriate analysis techniques used, including artificial intelligence. Even if two ships operate on the same route, their ratings can differ, and performing root cause analysis through data analysis can help identify the optimal operating patterns. The more data that is available, the better decisions can be made. Therefore, it is important to secure sufficient data over a period of three years until 2026 and prepare for the strengthened CII requirements in 2027.

To enhance CII, it is crucial to consider various technological and operational methods and compare and analyze them to find the most cost-effective and efficient solutions. Collaboration with technical providers, third-party verification agencies, and ports is essential to this process.

By adopting these approaches and fostering collaboration, the shipping industry can work towards improving CII and achieving the goals set out by the IMO in reducing carbon emissions.

Innovative Energy Saving Technology

KIM Sangyeob, Senior Surveyor of |

Selecting the appropriate

|

The total volume of greenhouse gases (GHGs) emitted by the shipping industry increases daily due to the surge in maritime traffic. In response, the IMO (International Maritime Organization) has established regulations to reduce GHG emissions from ships. The first, most economical, and practical measure to comply with these environmental regulations is to limit engine power, which naturally leads to ship speed reduction. However, ship’s speed directly influences its trade volume and cannot be arbitrarily restricted as it is regulated by the ship's operational plan. Consequently, it becomes crucial to adopt innovative energysaving technologies that can increase the ship's speed at the same engine power. This dual approach will both meet environmental regulations and maintain ship's target speed.

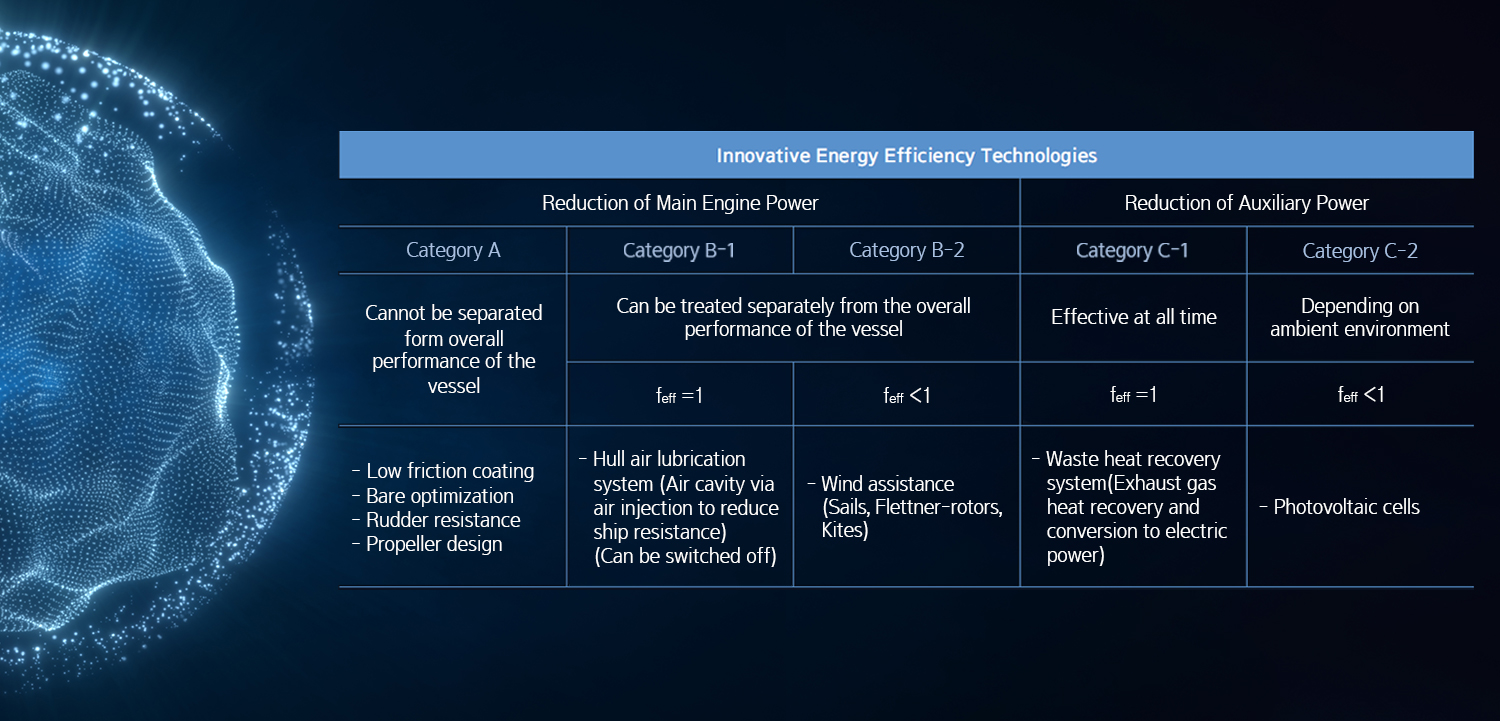

Innovative Energy Efficiency Technologies

The IMO categorizes innovative energy-saving technologies into Category A, Category B, and Category C, depending on the energy-saving power source (main engine or generator), physical characteristics of the device, and the impact of environmental factors on performance.

· Category A

Category A includes bulbous bow modifications, vortex flow control fins, rudder fins, ducts, and nozzles, etc. which are installed on the hull to contribute to drag reduction or increased propeller thrust. They are considered as an integral part of the hull and are not separated from the overall ship speed and power performance.

· Category B

In contrast, Category B comprise technologies that can be switched on and off so it can be distinguished by their energy savings separately from the ship’s overall speed and power performance. Recently popular technologies like Air Lubrication Systems (ALS) and Wind Assisted Propulsion Systems (WAPS) are classified as Category B.

Category B ① Air Lubrication Systems (ALS)

ALS is a technology that can reduce the main engine’s energy consumption by spraying fine air particles onto the ship’s bottom creating an air layer between the hull’s surface and the water, thereby reducing the resistance of the ship (frictional resistance). It is classified as Category B-1 because its energy-saving performance is independent of the environmental condition (wind, waves, etc.). For ALS to be effective, the air layer must be well retained on the ship’s bottom, so the energy-saving performance is significantly dependent on the ship’s draught and bottom shape. The main technical issues are the size and quantity of air particles sprayed onto the hull, along with the positioning and shape of the air nozzles. In addition, if the system is operated continuously, it can be expected to reduce fouling on the hull, which has an indirect energy-saving effect and maintenance cost benefits for the ship.

· Category B ② Wind Assisted Propulsion Systems (WAPS)

WAPS is a technology that generates propulsion from wind energy. Unlike ALS, which operates independently of the weather condition, WAPS’s energy saving performance is affected by wind speed and direction, so it is classified as Category B-2. There are several types of WAPS, including soft-sail, hard-sail (also referred to as a wing sale), and rotor-sail. Recently, hard-sail and rotorsail have been attracting attention. Hard-sail is a technology that generates ship propulsion by adjusting the wind’s angle of attack to create a speed difference in the air around the sail. Its performance varies depending on the cross-sectional shape of the sail. Rotor-sail technology on the other hand, generates propulsion by inducing a speed difference in the air around the sail (known as Magnus effect) by rotating a cylindrical sail. In essence, both hard-sails and rotor-sails share similar characteristics as they generate propulsion by adjusting the airflow around the sail. Both technologies also give high propulsion power near beamwind conditions.

The amount of thrust that can be obtained by a WAPS varies depending on the wind’s projected area. Hard sails hold the advantage of being installable on a larger scale than rotor sails. Rotor sails, however, have the benefit of generating a substantial amount of thrust relative to their size. Therefore, when considering the introduction of WAPS, it is essential to comprehensively consider the thrust to be obtained and the amount of available deck space. The main technical issues for WAPS are sail geometry (cross-section and aspect ratio), the relative interference effects of installing multiple sails, and the risk of resonance due to vortex shedding around the sails.

As we’ve discussed, the effectiveness of energy-saving technologies varies greatly depending on a vessel’s characteristics and its operational routes, Therefore, it is challenging to recommend a universally efficient energy-saving technology for all vessels. In order to choose an appropriate energy-saving technology, it is necessary to conduct comprehensive reviews of the ship’s size, design, and operating route, and to calculate the selected technology device’s specifications, taking into account initial investment cost and expected fuel savings.

Clear Path to Decarbonizing the Shipping Industry: Step-by-Step Response Strategy

HUR Yoonjung, Senior Surveyor of KR Business Support Team |

KR, a reliable partner

|

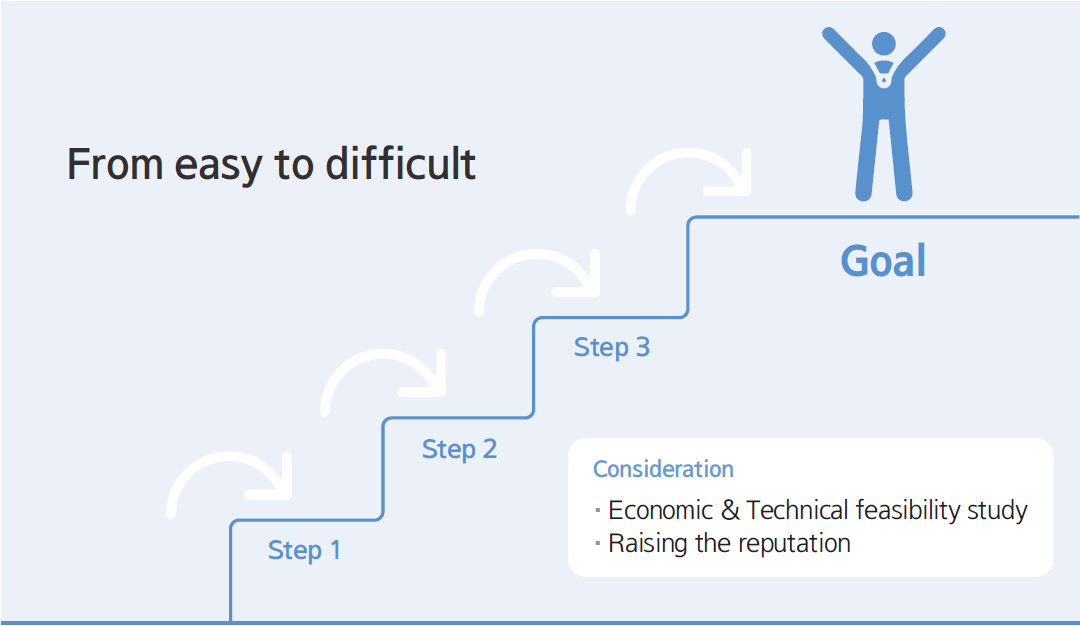

The Right Approach

The upcoming IMO MEPC meeting in July has captured the attention of maritime industry officials. During this meeting, revisions and strengthening of the initial strategy for greenhouse gas regulation, established in 2018, will take place. Additionally, the EU has separate plans for implementing the Emissions Trading System (EU ETS), and FuelEU Maritime which are penalty regulations based on life cycle evaluation. These regulations are set to be implemented sequentially from 2024 and are separate from the IMO.

Various private organizations, including finance, insurance, shippers, and charterers, are also evaluating the implementation of regulations using their own indicators. Consequently, shipping companies are facing significant challenges in finding comprehensive decarbonization solutions that comply with not only IMO regulations but also regional EU regulations and private requirements. As a result, the most common question shipping companies have these days is how to effectively respond to these diverse and strengthened regulations.

Greenhouse gas emissions from ships are influenced by numerous factors, including the ship’s design elements, operational patterns, and sea conditions. Uncertainty factors such as route, speed, weather, tide, cargo contracts, fouling, and anchoring time further complicate the search for solutions.

Given the complexity of these effects, it is important to explore multiple perspectives when seeking methods to reduce greenhouse gas emissions. Employing a one-size-fits-all approach is not advisable as it can be costly and ineffective in addressing all aspects simultaneously. Shipping companies should instead consider various possibilities and combine different methods. Furthermore, a customized approach that suits the specific characteristics of each shipping company, such as ship type and operational patterns, is necessary.

Consequently, adopting an approach that starts with the most easily implementable method and gradually incorporates more challenging methods is a recommended course of action. To facilitate this approach, in addition to the technical research conducted thus far, conducting economic feasibility studies will now be essential in determining the viability of these measures.

Priorities for Reducing GHG Emissions

· Step 1 | Identify GHG emissions and set reduction targets

First of all, shipping companies need to figure out the total GHG emissions and CII rating of all ships they own and simulate penalty costs for related regulations such as EU ETS and FuelEU Maritime. Based on this assessment, GHG reduction targets should be set for each individual ship.

· Step 2 | Improvement through operational measures

To begin the improvement process, it is recommended to focus on operational measures such as optimizing vessel speed and navigation routes, improving hull cleaning cycles, and minimizing anchoring time and ballast water usage. Additionally, it is essential to adopt a real-time monitoring and management platform that can oversee and control these measures effectively. In response to this need, several shipping companies are already implementing smart ship solution platforms across their fleet, starting with newly constructed ships. This trend has prompted the expansion of monitoring platform providers.

As it becomes evident that greenhouse gas-related regulations will not be one-time events but rather continually strengthened and updated, the implementation of a comprehensive platform for systematic management has become a necessity.

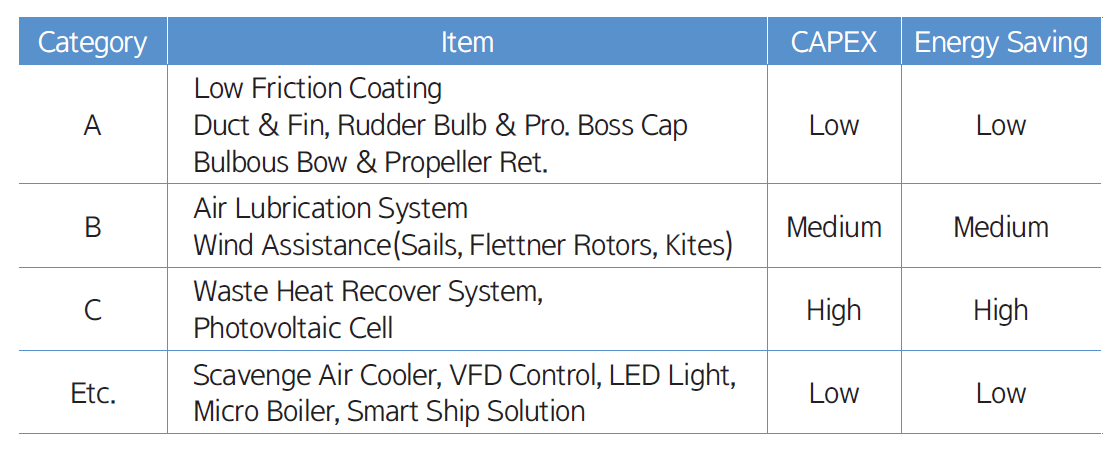

· Step 3 | Apply energy-saving technology

After implementing operational measures, another viable approach is to explore energy-saving technologies. These technologies encompass a range of energy-saving devices (ESDs) in addition to the smart ship solution platform mentioned in the previous step.

There are various energy-saving devices (ESDs) that can be considered for ships. These include well-known components such as ducts, fins, and rudder bulbs, which are typically installed in front or behind the propeller to enhance propulsion efficiency. Additionally, options like low-friction paint and air lubrication systems that minimize frictional resistance on ships are worth considering.

For main and auxiliary engines, implementing ESDs like scavenge air coolers, VFD control, LED lights, and micro boilers can be beneficial. Moreover, newer devices such as wind propulsion assistance devices and shaft generators have emerged as promising options. The development of on-board carbon capture systems is currently in its early stages. While there are still uncertainties surrounding the regulations associated with these systems, they are garnering attention as a solution that merits ongoing monitoring and evaluation

Categorization for EEDI calculation based on energy savings and characteristics

When considering the implementation of these technologies, it is crucial to carefully assess the actual application effect, cost implications, and installation timeline in relation to the specific vessel in question. The key is to select the optimal combination of technologies that aligns with the vessel's requirements and objectives.

· Step 4 | Transition to alternative fuels

Currently, it is not advisable to pursue modifications for converting existing ships to alternative fuels due to the significant additional costs and lengthy installation period involved. However, depending on the strictness of future regulations, this approach could be worth considering specifically for younger ships that still have a substantial amount of operating time remaining.

Biofuels are also very attractive options as they require few additional fuel storage tanks or systems, resulting in virtually no retrofit costs. The biggest constraint is whether a sustainable supply can be secured. Nevertheless, biofuel can be a good alternative for small ships where it is not easy to secure additional space for an alternative fuel storage tank.

Considering the escalating costs associated with stricter GHG reduction regulations, it is inevitable that existing ships will need to bereplaced with new ones at some point. With a typical ship lifespan of approximately 25 years, it is essential to incorporate the use of alternative fuels during the new construction phase, alongside design optimization and the application of suitable energy-saving devices (ESDs).

Before implementing alternative fuels, a thorough evaluation of technical and economic feasibility is crucial. This involves conducting a technical review of the ship’s design, taking into account factors such as the intended route, available bunkering ports, fuel tank type and arrangement. Based on these considerations, the capital expenditure (CAPEX) must be assessed. Additionally, the operating expenditure (OPEX) needs to be calculated, which includes evaluating the fuel costs associated with each alternative fuel, the penalty costs for GHG regulations, and maintenance expenses.

While precise calculations are challenging due to evolving technologies and uncertainties surrounding future GHG regulations, conducting this feasibility study serves as a foundational step in determining which alternative fuels are suitable for each ship’s specific requirements.

Bridging the Role of Operational Measures and Energy-Saving Technologies

In conclusion, shipping companies must continuously update their GHG emission reduction strategies by following the stepby-step approach outlined, to adapt to increasingly strict GHG regulations. Given the growing significance of energy security, as demonstrated by recent events such as the crisis in Ukraine, the transition to alternative fuels, as set out in Step 4, may not occur rapidly.

According to a report from Clarksons, the financing required for newbuilding projects over the past decade averaged $92 billion annually. However, the cost for fuel conversion over the next decade is expected to be 1.6 times higher. Moreover, considering the decarbonization scenario, it is projected that the cost will be 4.4 times higher by 2050. For shipping companies planning to construct new ships, this will undoubtedly pose a significant burden.

Consequently, the role of operational measures and energysaving technologies (Steps 2 & 3) as transitional solutions in the decarbonization process may receive increased attention. The possibility of policy regulations to incentivize their adoption cannot be dismissed either. Although this is undoubtedly a challenging journey for the shipping industry, it is crucial to effectively prepare for decarbonization by considering these factors.

KR plays a crucial role in assisting shipping companies with a stepby-step approach to decarbonization. Through the KR GEARS platform, CO2 emissions and Carbon Intensity Index (CII) ratings are provided to help companies track their progress. Furthermore, KR evaluates the anticipated penalty costs associated with the EU’s ‘FIT FOR 55’ regulations and assesses the economic feasibility of adopting alternative fuels.

GHG emission reduction strategies

Recently, KR has collaborated with multiple shipping companies to analyze the operational patterns of their entire fleets and develop tailored GHG emission reduction strategies. By working closely with these companies, KR aims to find collective solutions and serve as a reliable partner in the maritime industry’s response to decarbonization.