Inside KR

KR Decarbonization Magazine

VOL.08 | AUTUMN 2024

KR Enhances Korean-Flagged

Vessel Ratings Through CII

Calculation Error Correction

KR, in collaboration with the Ministry of Oceans and Fisheries, has corrected errors in the CII calculation and successfully reached an agreement on these amendments at the 81st IMO MEPC meeting. This revision benefits 76 bulk carriers and car carriers by improving their CII ratings by at least one grade.

What is Carbon Intensity Indicator (CII)?

The Carbon Intensity Indicator (CII) is an international regulation targeting ships engaged in international voyages with a gross tonnage of 5,000 tons or more. This regulation calculates the CII value based on the annual fuel consumption and the distance sailed by the ship, comparing it to international standards and assigning a grade from A to E. An A grade indicates the highest performance, while an E grade represents the lowest.

CII has been in effect since 2023, providing a standard for assessing the environmental performance of ships and reducing carbon emissions.

KR's Verification Results

Using 2023 IMO fuel consumption (DCS) data, KR verified the CII calculations for the affected ships.

Among the 101 bulk carriers over 279,000 DWT and vehicle carriers over 57,700 GT, 76 ships, accounting for 75%, showed an improvement of at least one grade in their CII rating as a result of the corrected calculation error.

(Unit: Number of ships)

| Number of KR-Verified Ships for CII |

Changes in CII Ratings | |||

|---|---|---|---|---|

| +1 Grade | +2 Grade | +3 Grade | ||

|

Bulk Carriers (Over 279,000 DWT) |

41 | 23 | 17 | - |

|

PCTC (Over 57,700 GT) |

60 | 24 | 11 | 1 |

Calculation Error and Correction

KR discovered that, instead of applying the actual capacity (DWT or GT) of ships, an incorrect fixed value was applied to large bulk carriers over 279,000 DWT and vehicle carriers (PCTC) over 57,700 GT.

This resulted in these ships being assigned lower CII grades, potentially disadvantaging the competitiveness of South Koreanflagged ships in the field of greenhouse gas reduction.

Importance of CII Ratings

If a ship receives a CII rating of D for three consecutive years or E in any single year, it must establish a Corrective Action Plan (CAP) to comply with IMO regulations. However, vessels with low CII ratings may face various economic disadvantages due to the nature of the commercial shipping market.

For instance, such disadvantages may include reduced secondhand vessel transactions, decreased profitability from installing eco-friendly equipment or operating at reduced speeds to meet regulations, exclusion from port fee reduction incentives at certain ports, rejection in the charter market, and diminished residual value of second-hand vessels.

With the recent correction of the CII calculation errors, some national ships have now received accurate CII ratings in a timely manner. KR will continue to work with relevant authorities to enhance the competitiveness of South Korean-flagged vessels following IMO regulatory updates. Meanwhile, the IMO plans to complete revisions of related regulations, including the short-term measures for greenhouse gas reduction and the CII rating system, by January 1, 2026.

KR Conducts Risk Assessment on Korea's First Onboard Carbon Capture System

KR has announced the successful installation of an onboard carbon capture system (OCCS) with purely domestic technology, and it will soon undergo internal verification testing.

The project began in April 2023 as a collaborative effort with HMM, Samsung Heavy Industries (SHI), and PANASIA. As a result of this collaboration, the system was installed on the 2,200 teu container ship, HMM Mongla. KR conducted the risk assessment and application of relevant regulations in this OCCS project.

The OCCS applies a technology that captures, liquefies, and stores carbon dioxide from the exhaust gases generated during the ship’s operation. This technology has the potential to be recognized by international organizations such as the International Maritime Organization (IMO) as one of the most promising carbon reduction technologies, making it a proactive solution for reducing greenhouse gas emissions from ships in the future.

Amidst the growing global interest in carbon capture technology, this system is expected to demonstrate technological leadership in the international maritime industry. It is hoped that this will assist global maritime leaders when they meet to discuss the possible future adoption of OCCS at the meeting of the IMO’s Marine Environment Protection Committee.

A KR official stated, "Carbon capture technology is highly regarded as one of the effective measures for reducing greenhouse gases, drawing significant attention from the international community and the shipping industry. Based on the experience and outcomes of this successful project, KR will make every effort to support the shipping industry in timely decarbonization."

In July 2021, the European Commission announced the 'EU Fit for 55' plan aimed at reducing greenhouse gas emissions. The goal of this plan is to cut emissions by 55% compared to 1990 levels by 2030.

As part of this initiative, the FuelEU Maritime regulation has been introduced. This regulation is designed to encourage vessels calling at ports in Europe and the European Economic Area (EEA) to use renewable and low-carbon fuels.

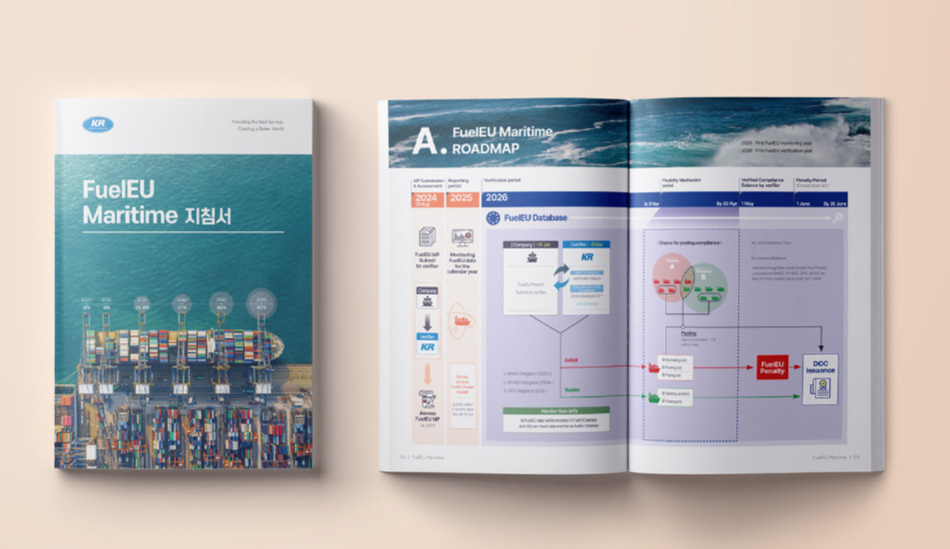

In response, KR has published a new guideline to help shipping companies effectively comply with the FuelEU Maritime regulation. Starting from August 1, 2024, this guideline will be available through KR-GEARs and will provide instructions on developing and submitting the Monitoring Plan to verification bodies. Shipping company representatives are encouraged to refer to this guideline for their operational needs.

New Release:

FuelEU Maritime Guidelines

In July 2021, the European Commission announced the 'EU Fit for 55' plan aimed at reducing greenhouse gas emissions. The goal of this plan is to cut emissions by 55% compared to 1990 levels by 2030.

As part of this initiative, the FuelEU Maritime regulation has been introduced. This regulation is designed to encourage vessels calling at ports in Europe and the European Economic Area (EEA) to use renewable and low-carbon fuels.

In response, KR has published a new guideline to help shipping companies effectively comply with the FuelEU Maritime regulation. Starting from August 1, 2024, this guideline will be available through KR-GEARs and will provide instructions on developing and submitting the Monitoring Plan to verification bodies. Shipping company representatives are encouraged to refer to this guideline for their operational needs.

KR Celebrates Arrival of Innovative

Low-Carbon Sailing Cargo Ship

"SV Juren Ae" in the Marshall Islands

On July 31st, KR proudly announced the successful delivery of the innovative low-carbon sailing cargo ship, SV Juren Ae (IMO no. 1021245), to the Marshall Islands Shipping Corporation (MISC).

Funded by the International Climate Initiative (IKI*), this vessel is the result of a collaborative effort led by the German International Cooperation Agency (GIZ), as part of the project "Transition to Low-Carbon Sea Transport in the Republic of Marshall Islands" launched in 2017 by the German Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection (BMUV). Key project partners include KR, the University of Applied Sciences Emden/Leer, MISC, Asia Shipbuilding Co. Ltd., and Kostec Co. Ltd., among others.

*International Climate Initiative (IKI): A climate protection program funded by the German government, supporting global projects that address climate change and environmental protection.

The SV Juren Ae boasts several innovative features, including the Indosail-Sailing Rig system. This partially automated sail system, designed by the German naval designer HSVA and inspired by traditional Indonesian sails, is complemented by installed photovoltaic (PV) units and a hybrid power system, resulting in a reduction of CO2 emissions by approximately 80% compared to similar-sized ships.

The ship’s propeller and engine are used for low-speed maneuvering, while the propeller also functions as a turbine to generate electricity. This innovative design enables a ship to achieve a service speed of approximately 12 knots (about 22.2 km/h) under sail, and around 7 knots (about 13 km/h) with the auxiliary diesel engine. Additionally, the ship is equipped with a battery system charged by surplus wind power, allowing for electric propulsion during low-speed operations.

KR regards the success of the SV Juren Ae project as a significant milestone that demonstrates the feasibility of sustainable technologies in the maritime industry. With the increasing pressure of global greenhouse gas regulations, KR remains committed to supporting innovative technology projects that help customers adapt flexibly.

The SV Juren Ae will be operated by MISC in the Marshall Islands and the broader Pacific region, offering a promising solution for low-carbon maritime transport, particularly in regions with high fuel prices like the Pacific islands.

KR Partners with HD Hyundai to Develop

MW-Class Hydrogen Engines for Ships

KR (Korean Register) has launched a collaborative initiative with HD Korea Shipbuilding & Offshore Engineering (HD KSOE) and HD Hyundai Heavy Industries to develop core technologies for megawatt (MW)-class hydrogen engines for ships.

The MW-class hydrogen engine project represents a key advancement in marine mobility, designed to meet International Maritime Organization (IMO) greenhouse gas regulations. This initiative falls under the 2024 Materials and Components Technology Development Program, a government-supported effort led by the Korea Planning & Evaluation Institute of Industrial Technology (KEIT). Specifically, the project focuses on developing and evaluating critical materials and components for hydrogen injection and supply systems in MW-class internal combustion engines.

Hydrogen-powered engines, which produce zero emissions, present a cost-effective, safer, and more durable alternative to hydrogen fuel cells, particularly in large-scale applications. Notably, MW-class hydrogen engines boast an energy conversion efficiency close to 50%, giving them a competitive edge as an eco-friendly power source suitable for medium to large vessels and hydrogen carriers.

At the heart of this joint project lies the high-capacity direct hydrogen injection system, a crucial component for marine internal combustion engines. While no commercially viable solution currently exists, expectations are high given the participation of HD KSOE and HD Hyundai Heavy Industries, which successfully developed Korea’s first 1.5MW LNG-hydrogen dual-fuel engine. This synergy is anticipated to drive meaningful progress in the commercialization of hydrogen-based propulsion systems.

KR will collaborate with 16 partners, including the two HD Hyundai affiliates, to develop hydrogen injection and supply systems for MW-class engines. The project will also involve integrating the technology into HiMSEN engines, with comprehensive land-based performance demonstrations planned. KR will serve as the lead research institution for the four detailed consortiums involved and will oversee one of the core sub-projects. With a government R&D budget of approximately KRW 13.9 billion (USD 10.4 million) allocated through 2027, the project is poised to accelerate Korea’s entry into the green engine market.

Kim Dae-heon, EVP of KR R&D Division, stated, “This joint research initiative will establish the foundation for 100% hydrogen-fueled direct injection engines, enabling Korean shipbuilders to lead in the eco-friendly engine market. KR remains committed to advancing technologies that meet environmental regulations and will continue to provide extensive support to clients and the wider maritime industry”.

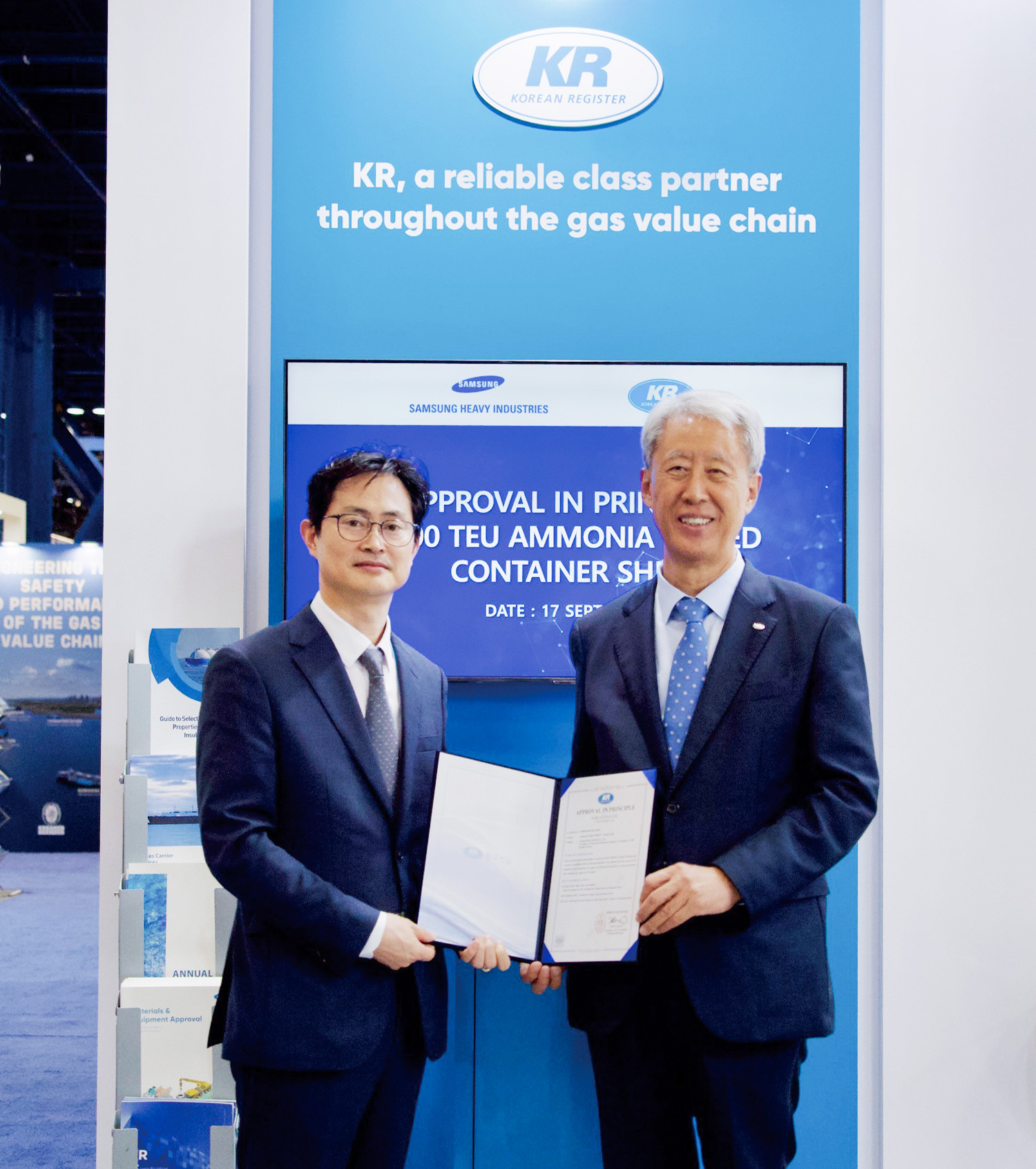

KR Grants Approval in Principle

to Samsung Heavy Industries for

9,300 TEU Ammonia-Fueled Container Ship

At GASTECH 2024, KR (Korean Register) announced that it has awarded an Approval in Principle (AiP) to Samsung Heavy Industries (SHI) for their “9,300 TEU Ammonia-Fueled Container Ship”.

As the global maritime industry intensifies efforts to meet stricter decarbonization targets, ammonia is gaining prominence as a potential zero-carbon fuel. In light of the current trends, recent LNG-fueled container ships have adopted designs that allow the use of ammonia fuel for its sustainable option.

Ammonia fuel presents advantages in terms of cost-effectiveness and efficiency compared to other alternative fuels. However, due to its high toxicity and corrosive properties, it requires a specially designed fuel propulsion system, as well as additional safety assessments that take the operational requirements into consideration.

The development of this 9,300 TEU ammonia-fueled container vessel marks a key step in advancing ammonia fueled propulsion technology.

SHI have developed an entirely new structural layout and the vessel’s design which includes specialized fuel tanks, fuel supply systems, ventilation, and gas detection systems, incorporating the unique properties of ammonia fuel.

KR verified this newly developed vessel’s design and ammonia fuel system, ensuring compliance with classification rules and international regulations, and granted AiP after confirming the integrity and safety of the entire system.

LEE Hyungchul, Chairman and CEO of KR, said: "This joint development is a significant step toward the commercialization of large ammonia- fueled container ships. KR will continue to provide technical support for the innovations in decarbonization solutions."

JANG Haeki, Executive Vice President and CTO of SHI, said: "Our 9,300 TEU ammonia- fueled container ship incorporates the leading eco-friendly technologies of SHI. We will continue to accelerate the development of carbon-neutral solutions to secure our competitive edge in the next-generation ship market."

KR and HD Hyundai Heavy Industries

Engage in Joint Development of Enhanced

Ammonia Fuel Supply System

through Risk Assessment

At GASTECH 2024 in Houston, KR (Korean Register) announced on September 17 that it has signed a Memorandum of Understanding (MoU) with HD Hyundai Heavy Industries (HD HHI) to develop an enhanced ammonia fuel supply system.

The International Maritime Organization (IMO) has established a target to achieve Net-Zero greenhouse gas emissions by 2050.

In line with this regulatory goal, there is a global acceleration in the development of alternative fuel technologies.

Ammonia is emerging as a promising alternative fuel due to its sustainable advantages, including ease of storage and transportation, and avoidance of the emission of carbon and sulfur compounds.

This agreement represents a collaborative effort between HD HHI and KR to advance the development of an ammonia fuel supply system. HD HHI will design key system configurations to integrate ammonia fuel into ammonia carriers. KR will conduct a comprehensive risk assessment of the system and grant an Approval in Principle (AiP).

JUNG Jaejun, Executive Vice President of HD HHI, remarked: "Ammonia, as a zero-carbon fuel, offers significant benefits in operational economics and supply stability. Through this risk assessment, we are dedicated to developing an enhanced ammonia fuel supply system, contributing to global carbon-neutral initiatives."

KIM Yeontae, Executive Vice President of KR’s Technical Division, added: "This joint development is an important foundation for the commercialization of ammonia-fueled vessels. KR will continue to provide essential technical support for advancing decarbonization solutions.”

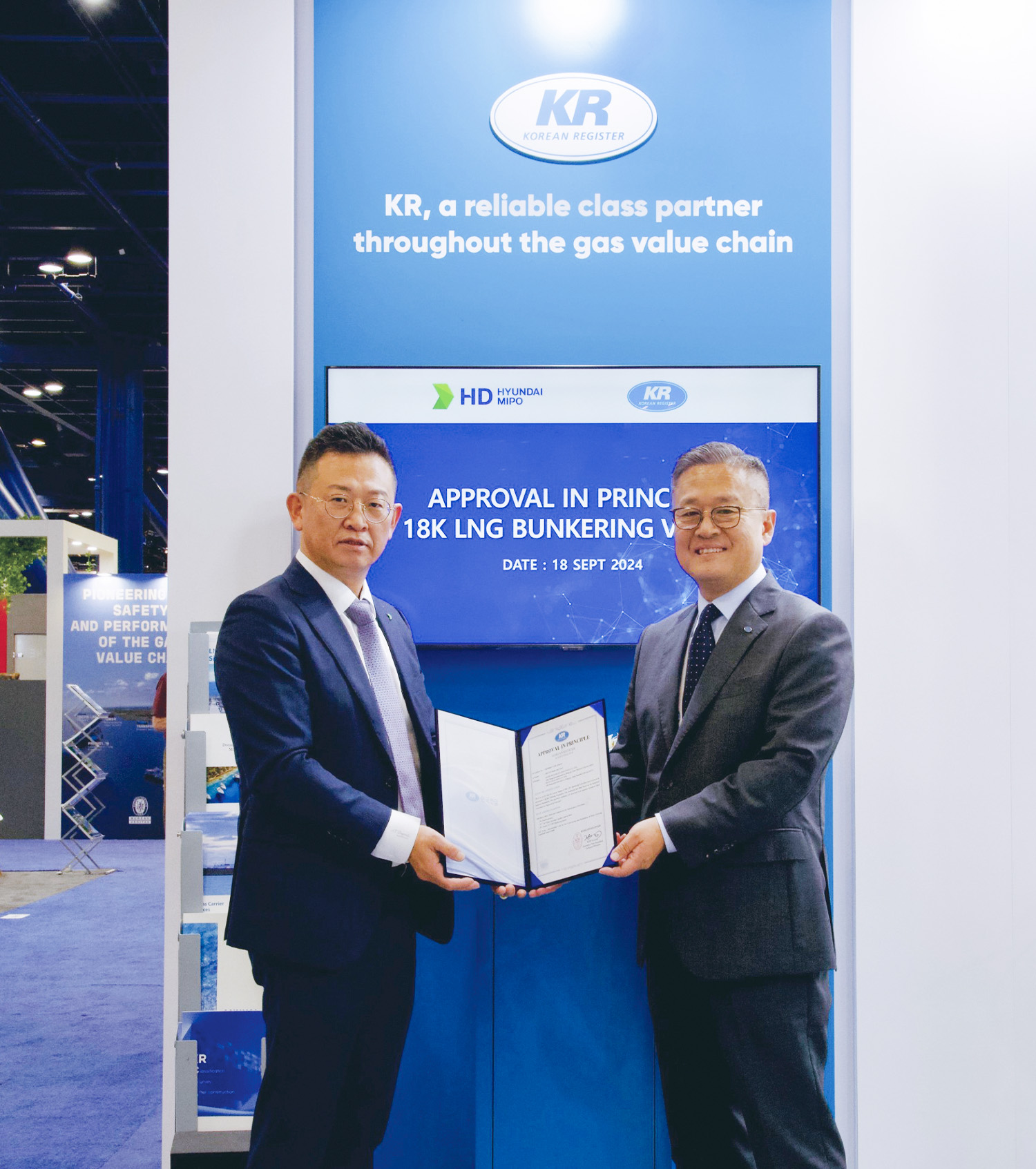

KR Grants AiPs to HD Hyundai Mipo's

Innovative Ammonia and

LNG Bunkering Vessels

KR (Korean Register) has awarded an Approval in Principle (AiP) to HD Hyundai Mipo (HD HMD) for their innovative 23K Ammonia Bunkering Vessel and 18K LNG Bunkering Vessel on September 18, at GASTECH 2024, paving the way for green shipping.

The development of these vessels represents a significant advancement in the maritime industry’s efforts to meet the International Maritime Organization’s (IMO) ambitious greenhouse gas reduction targets, which include at least 20% by 2030 and 70% by 2040, with a goal of achieving Net-Zero emissions by 2050.

The IMO's move has galvanized the industry to explore cleaner maritime bunker fuels, with ammonia emerging as a promising solution due to its zero carbon emissions and low technical barriers. Leading global shipping and energy companies

are intensifying their focus on developing ammonia engines and fuel cell systems to commercialize decarbonized vessels.

At the same time, as many shipping companies have adopted LNG as a transitional fuel, the demand for LNGfueled vessels is growing steadily, which has also led to increasing interest in LNG bunkering vessels.

In response to this emerging trend, KR and HD HMD have been leading in addressing the challenges associated with this transition.

HD HMD developed the initial design for the 23K ammonia bunkering vessel, tailoring the cargo system to the distinctive properties of ammonia. KR conducted a rigorous review of the design, assessing it against classification rules and applicable domestic and international regulations, ensuring the design’s safety and compliance with industry standards and granted AiP to the vessel as a result.

On the same day, KR granted another AiP to HD HMD’s 18K LNG bunkering vessel. HD HMD, leveraging its expertise in gas carrier technology, led the initial design and developed the cargo systems for the vessel. KR reviewed the design in line with classification rules and domestic and international regulations, confirming its safety and compliance.

Dong-jin LEE, Head of Initial Design Division at HD HMD, said: "Ammonia and LNG are rapidly gaining traction as lowcarbon alternative fuels. As the number of vessels powered by these fuels increases, we anticipate a rising demand for ammonia and LNG bunkering vessels. With these AiPs from KR, HD HMD has not only laid the groundwork for the commercialization of ammonia bunkering but has also secured a diverse portfolio of bunkering vessels, aiming to take a leading position in the construction of bunkering vessels.”

Yeontae KIM, Executive Vice President of KR’s Technical Division, said: "The collaborative development of the 23K ammonia bunkering vessel and the 18K LNG bunkering vessel is highly significant as the maritime industry increasingly focuses on alternative fuels to meet environmental regulations. KR is committed to ongoing technical support for developing environmentally friendly ships and technologies and guiding our customers through the energy transition."